REACTIVE GROUND Services

QMR Blast provides Reactive Ground Services for mine sites throughout Australia. We can come to the site and/or provide advice to determine the risk of reactivity.

Patent Number 2021201993

Services include:

1. Sulphide assay

2. Reactivity risk assessment based on sample pH, carbonate content and the presence of sulphide.

3. Correct sampling using rotary dividers/riffle splitters, elimination of heater block induced effects on sample temperature response and availability of time lapse video and monitoring of NOx during testing.

+ WHAT IS REACTIVE GROUND TESTING?

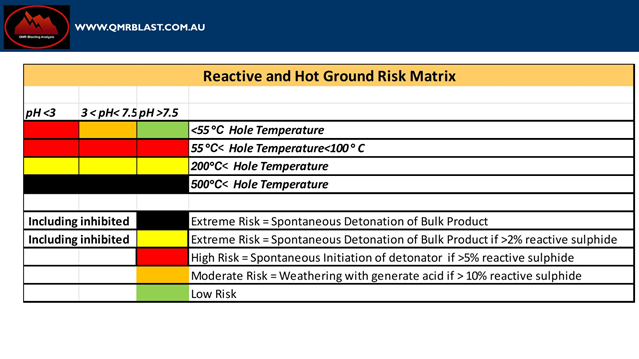

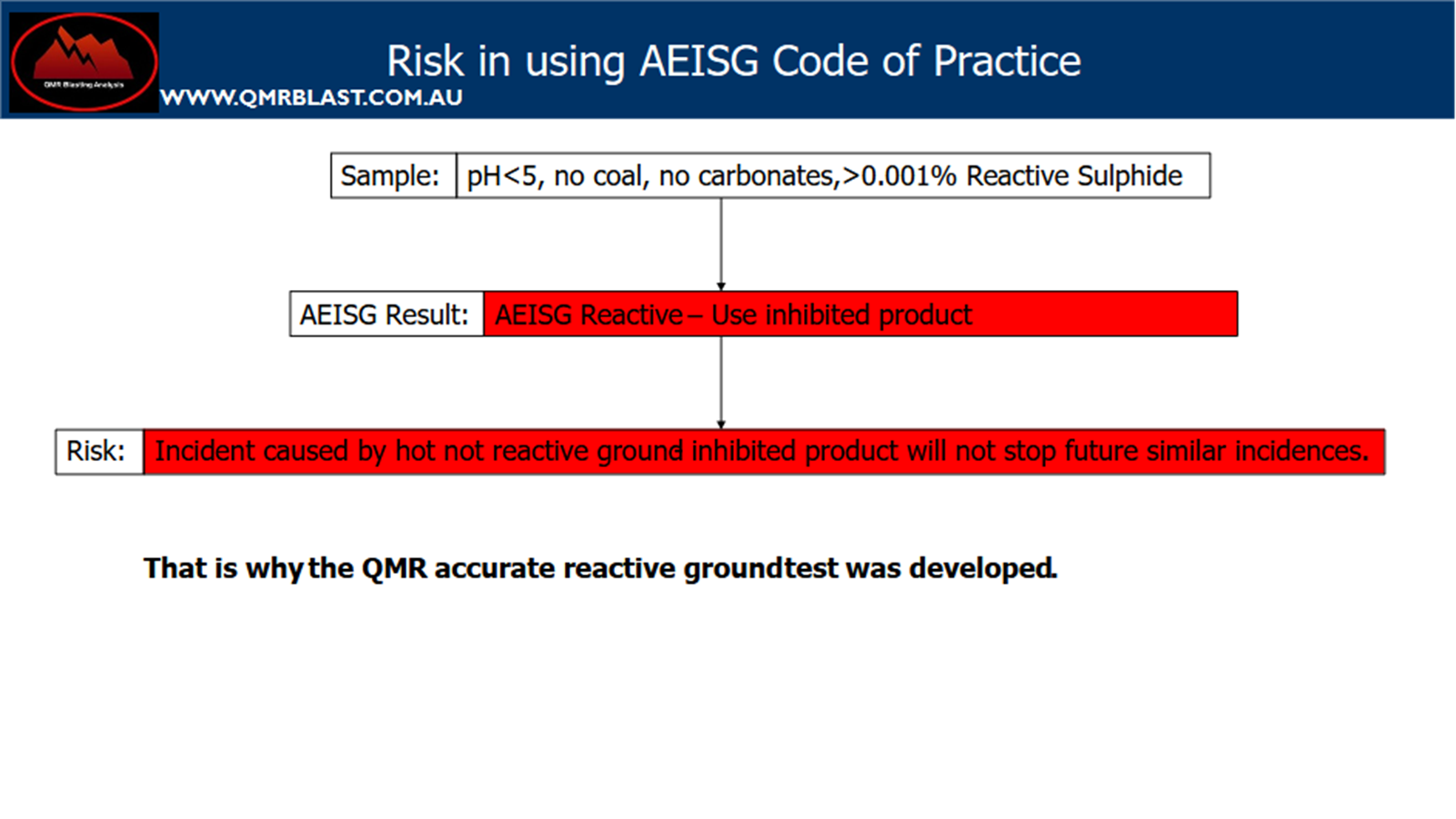

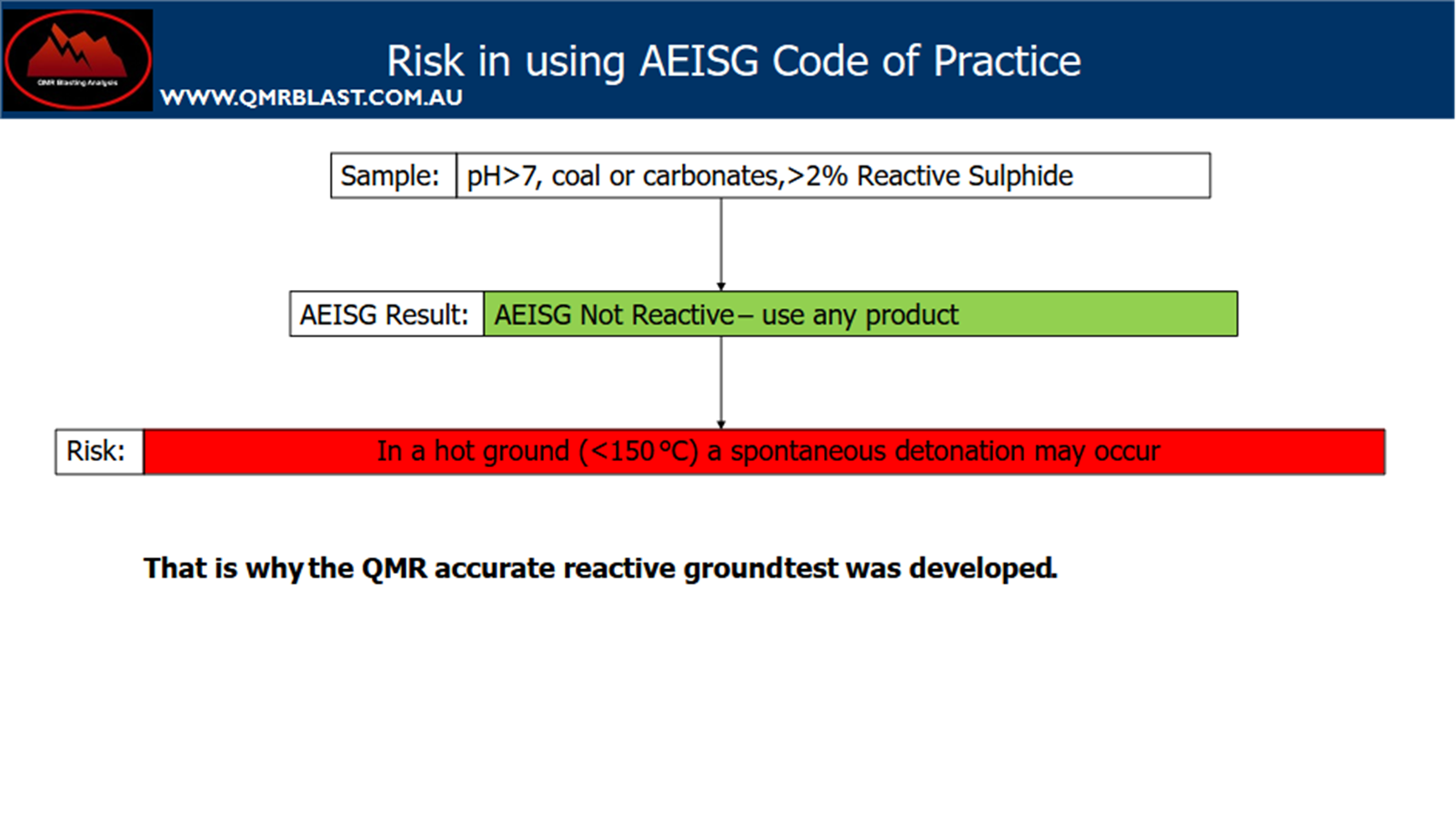

Nitrates contained in bulk explosive products can react with sulfides contained in the ground surrounding the blast hole. Spontaneous reactions may result in premature detonation of blast holes with associated safety hazards. This results in significant productivity decreases as only small blocks can be blasted to limit the duration that the products sleeps in the hole.

Alternatively, more expensive explosive formulations are proposed, which may not be completely immune to reactivity.

In Australia, reactive ground testing is carried out annually with 12 rock samples tested. The testing consists of mixing crushed rock with ammonium nitrate and weathering agents and placing the sample in a heater block set at a temperature of 55oC(131F). A thermocouple is placed in each sample to monitor the temperature over the test period. Should the temperature rise more than 2OC (3.6F) above the 55OC (131F) block temperature it is deemed reactive (Anon, 2013). A written report on the reactivity testing is sent to the site.

THE PROBLEM WITH TRADITIONAL TESTING METHODS

a. Samples may oxidize during milling.

b. The milling process is likely to segregate particles and resulting grab sample will not be representative.

c. Test tubes in a heater block are inherently difficult to maintain at 55°C.

d. The heater block can prevent a reactive sample from reacting by absorbing heat and quenching the reaction.

e. The heater block can transfer heat from a reactive sample to an adjacent non-reactive sample and produce a false positive test.

f. It is difficult to observe reactions and resulting NOx emissions because the samples are inside a heater block and only visually monitored at the beginning and conclusion of the test.

To solve these issues, a new procedure was required.

THE QMR BLAST METHOD

GREATER TEMPERATURE CONTROL, STABILITY AND INCREASED VISIBILITY

We mill all samples under vacuum to prevent oxidization. Dry samples are riffle split and wet samples are split with a rotary divider. Riffle splitting /rotary dividing ensures that the sample is representative.

We replace the heater block with an oil bath. This has the additional advantage of allowing more stable temperature control due to the continual mixing of the oil in the bath.

Our oil bath approach also allows a time lapse video to be taken for the duration of the test because the samples can be observed.

Oil Bath Test Samples